Robotics system stands out among the many technical breakthroughs because it has continually captivated the public’s imagination and expanded the limits of what is possible.

The area of robotics and automation has developed significantly over the years, changing whole sectors, altering our everyday lives, and even altering our definitions of labor and artistic expression.

As we approach a new age, it is essential to investigate the far-reaching effects of robotics and automation on culture, industry, and more.

So let’s get into our main topic starting with-

What is Robotics?

As a field of study, robotics systems encompass a diverse range of disciplines. It involves utilizing scientific principles and technological advancements to design, develop, and use robotic systems.

In the realm of technology, a robot can be defined as an autonomous or semi-autonomous machine that exhibits remarkable self-sufficiency, requiring minimal human intervention.

These advanced robotics and automation systems possess the extraordinary ability to perform tasks with unparalleled precision, accuracy, and efficiency, surpassing the capabilities of their human counterparts.

In manufacturing facilities, advanced robotic arms are utilized to assemble various items.

At the same time, in healthcare institutions and other social environments, highly sophisticated humanoid robotics projects are employed to engage in interactive interactions with individuals.

The History of Robotics Technology

People have been fascinated by robotics projects or self-operating devices that can carry out specific jobs for generations.

The fascinating trip through time that is the history of robotics and automation, from its earliest mythical and mechanical wonders to today’s state-of-the-art robots, offers a window into the technical and creative ambitions of human being.

Early Automata, Mythology, and the Past

Ancient cultures’ depictions of automatons and other artificial entities in myths and legends provide a foundation for modern robotics systems.

Hephaestus, the Greek god of artistry, built robotics projects to help him.

In Jewish tradition, the fabled Golem was a creature made of clay that came to life to serve and defend its creators.

The Invention of Automata and the Birth of the Renaissance

Medieval and Renaissance-era inventors and artisans widely explored mechanisms that replicated human and animal movements.

The Ban Ms brothers of Baghdad also constructed mechanical devices in the 9th century.

At the same time, Leonardo da Vinci’s detailed drawings included concepts for mechanical knights and automated musical instruments.

18th and 19th Centuries Industrial Revolution

The advent of the Industrial Revolution was a watershed moment for robotics and automation.

Inventors like Jacques de Vaucanson built automata to mimic human actions; for example, they made a mechanical duck that could eat and digest its meal.

These first efforts paved the way for the construction of later, more sophisticated devices.

“Robot” as a noun first appeared in the Early 20th century.

The Czech playwright Karel Apek coined the word “robot” in 1920 with his play “R.U.R. (Rossum’s Universal Robots).

Artificial entities designed to do human work were called robots in the play. “robot” comes from the Czech word “robota,” which refers to involuntary labor.

As we know it now, the notion of robotics systems may be traced back to Apek’s writings, which sparked public interest in self-operating machines.

When Industrial Robots First Began to Gain Popularity, Midcentury

After WWII, robotics system development picked up speed.

The first industrial robot, the Unimate, was created by George Devol and Joseph Engelberger in 1954 and was employed for die-casting tasks in factories.

This event heralded the beginning of industrial robots and automation.

Developments in Robotics and Space Travel in the late 20th Century

With the development of new technologies, robots soon found uses outside of manufacturing.

Researchers in the 1960s and 1970s at places like Stanford University created more precise and adaptable robotic arms.

The medical and aerospace industries both made use of these arms. Mars Exploration Rovers Spirit and Opportunity demonstrated the potential of robotic exploration in the early 2000s.

Robotics Projects in the 21st Century

In the 21st century, robots have rapidly spread to new areas of life.

There has been an increase in the availability and incorporation of robotics and automation in various settings, from consumer products like the Roomba vacuum to healthcare.

Humanoid robots are expanding the capabilities of robots in areas such as mobility, communication, and social interaction, with the likes of Boston Dynamics’ Atlas and Hanson Robotics’ Sophia.

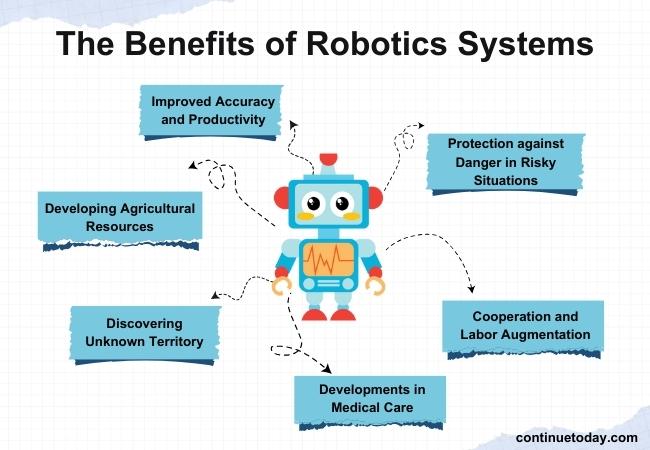

The Benefits of Robotics Systems

Few technological advancements have captivated the world’s imagination and promise as robotics and automation.

Robotic systems have revolutionized a wide range of fields and increased human potential in ways that were previously the stuff of science fiction.

This section of this article explores the many areas and aspects of life that robotics and automation improve.

- Improved Accuracy and Productivity

- Protection against Danger in Risky Situations

- Cooperation and Labor Augmentation

- Developments in Medical Care

- Discovering Unknown Territory

- Developing Agricultural Resources

Improved Accuracy and Productivity

The increased productivity and accuracy across several sectors are one of the robots’ most evident and consequential advantages.

Robotics projects thrive on jobs that need precise, repetitive motions. Robots, for example, can construct items with more speed and uniformity than humans.

Because of this, manufacturing rates and faults go down, resulting in better goods.

Moreover, some of the world’s most intractable problems may be solved through robotics and automation technology.

Rescue workers may use robots to aid search and rescue, supply distribution, and damage assessments.

There will be less strain on caregivers and healthcare institutions if robots are there to help older people.

Protection against Danger in Risky Situations

Robots may instead perform tasks that humans find too risky or harmful.

Robotics projects may be used in high-risk environments like nuclear power plants and deep-sea research.

This is particularly apparent in disaster response situations when robots sift through the rubble and search for survivors in locations where human rescuers would be in grave danger.

Cooperation and Labor Augmentation

Humans should not be afraid of robotics engineering taking their jobs since they can increase human efficiency and contentment with the work.

Cobots, or collaborative robots, are built to aid people when human power, accuracy, or speed are needed.

Working together frees people to exercise the kinds of imagination, analysis, and judgment that machines cannot yet match.

Developments in Medical Care

The use of robotics engineering is rapidly expanding in the medical industry.

Minimally invasive surgeries performed by surgical robots are more precise, leading to faster healing and fewer problems.

Robots used in rehabilitation procedures may restore patients’ movement and strength.

Robots used in telemedicine allow doctors to consult with patients remotely, expanding access to medical treatment in underdeveloped regions.

Discovering Unknown Territory

The development of robotics engineering has been crucial to extending human civilization’s influence beyond Earth.

Space missions have used robots to collect data, evaluate materials, and conduct experiments in places inaccessible to people.

The Mars rovers and other robotics projects have uncovered a wealth of information on the red planet’s geology and habitability.

Developing Agricultural Resources

Robotics projects are changing the face of farming in a big way.

Robots in the agricultural sector can now plant seeds, irrigate crops, and gather produce with pinpoint accuracy, significantly improving efficiency and decreasing waste.

This practice results from improved agricultural yields, reduced need for chemical fertilizers and pesticides, and an overall lessening of their environmental impact.

Types of Robotics Systems

Robotics projects are a broad discipline since many distinct robot designs are suitable for a wide range of applications.

According to their specific traits and usefulness, the following are some of the most often-seen forms of robotics and automation-

- Industrial Robots

- Cobots, or Collaborative Robots

- Mobile Robots

- Service Robots

- Medical Robots

- Agricultural Robots

- Exploration Robots

- Mechanical Robots

- Robots in Education

- Robots in Research

- Robots for Defense

- Social Robots

Industrial Robots

In the manufacturing and industrial sectors, the industrial robotics engineering sector plays a vital role.

Typical applications of this kind of robot include welding, material handling, painting, and packing. Factory output is increased because of the efficiency and accuracy of these robots.

Cobots, or Collaborative Robots

Cobots are collaborative robots that can function in the same office as people.

This robotics engineering sector is equipped with cutting-edge safety measures that completely risk-free human and robot interaction. Machines and people work together in factories and assembly lines using cobots.

Mobile Robots

Mobile robots can navigate their environments without human guidance.

That robotics engineering system might be on the ground, in the air (as drones), or even in the sea.

Applications for mobile robots include supply chain management, inventory control, mining, patrolling, and farming.

Service Robots

When it comes to helping people, service robots are where it is. They work in many fields, from medicine and nursing to tourism and grocery stores.

Robotics and automation for housekeeping, telepresence for long-distance conversation, and package delivery are just a few examples.

Medical Robots

Surgery, diagnosis, and general patient care are just some of the many applications of medical robots in the healthcare industry.

Medical robotics projects include robotic-assisted surgery, rehabilitation robots, and telemedicine robots.

Agricultural Robots

Automating repetitive farm operations like planting, harvesting, and checking on the health of crops is the primary function of agricultural robots.

These robotics and automation can boost productivity, lessen the need for human labor, and better use available resources.

Exploration Robots

Robots designed for exploration are used where people would be at risk or unable to go alone.

Exploration rovers, remotely operated vehicles (ROVs) for use in the ocean, and rescue robots are just a few examples.

Mechanical Robots

The purpose of entertainment robotics and automation is to provide amusement and human interaction.

Theme park animatronics, robotic pets, and stage robots are all examples.

Robots in Education

Programming, engineering, and problem-solving are just some talents that educational robotics engineering aims to instill in kids of all ages.

Educative institutions and programs often make use of such robots.

Robots in Research

Scientists and researchers use research robots to test novel technologies, investigate human-robot interaction, and make strides in robotics and automation.

These robots aid in the research and creation of cutting-edge computing methods, sensors, and regulatory frameworks.

Robots for Defense

Defense uses for military robots include surveillance, reconnaissance, bomb disposal, and remote warfare.

These robotics engineering systems aim to make hazardous circumstances safer for human troops.

Social Robots

Social robotics and automation systems are programmed to engage in social and emotional interactions with humans.

They have many applications, including healthcare, rehabilitation, education, and companionship for older people and others with extra care.

Key Characteristics of Robotics Systems

Robotics and automation is an ever-evolving and interdisciplinary field that seeks to design and build autonomous or partially autonomous robots.

The traits that constitute robotics systems are ever-evolving, influencing how these robots interact with and affect human beings.

In this piece, we will go into the fundamentals of robotics and what makes the field tick-

- Freedom and Mechanical Work

- Senses and Perception

- Movement and Actuation

- Modifiability and Educative Capacity

- Involvement of Robots and People

- Adaptability and Uses

Freedom and Mechanical Work

Robots’ capacity for independent action is one of their distinguishing features.

Robot operating systems are built to carry out activities with varied degrees of independence, meaning they do not need continual supervision.

This might include everything from routine, predetermined actions to complex, data-driven decision-making.

Robot operating systems play a vital role in the growing trend of automation, which entails creating systems that can carry out functions without human involvement.

Senses and Perception

Sensors provide robot operating systems insight into their surroundings so they may engage with them. The term “sensors” may refer to a wide variety of devices.

Robots’ ability to take in and make sense of sensory information is fundamental to their capacity for locomotion, obstacle avoidance, and object/human interaction.

Movement and Actuation

Robots’ actuation is their mobility and capacity to control their surroundings.

Mechanisms like motors, servos, and hydraulic systems provide robot operating systems with the ability to accomplish tasks in the real world.

The ability to move about is vital because it lets robots function in many different settings.

Robot operating systems may be as basic as wheels or as complicated as legs, wings, or even the ocean.

Modifiability and Educative Capacity

These days, robots can learn from their mistakes and quickly adapt to new environments.

Robots’ abilities may be refined over time using machine learning algorithms, which analyze data and modify their actions.

This quality shines most in endeavors when uncertainty and change are present.

Involvement of Robots and People

HRI, or human-robot interaction, is when a robot works with a human being.

Some examples of this include talking, gesturing, and reading body language and tone of voice to decipher human emotions.

Human-robot interaction (HRI) technology has progressed so that robot operating systems may now operate side by side with humans in fields including manufacturing, healthcare, and customer service.

Robots’ programmability is another great benefit.

Robots are more adaptable in dynamic settings than fixed equipment because they may be repurposed to take on new roles with little downtime.

Adaptability and Uses

Robotics engineering may be used for everything from exploration, medicine, manufacturing, and even the entertainment industry.

Robots are used for various tasks, from product assembly to surgery to exploration of unexplored territory and even audience entertainment.

This flexibility demonstrates the remarkable potential of robotics and automation.

Ethical and societal concerns are growing significantly as robots become more pervasive.

Complex moral problems need cautious examination and regulation, including questions of employment displacement, privacy, security, and the possibility of robot solutions making autonomous judgments that affect people.

Current Trends Shaping the Future of Robotics

The field of robotics is constantly evolving, driven by rapid advancements in technology and innovative applications.

From manufacturing to healthcare, exploration to entertainment, robotics is breaking the boundaries of what machines can achieve.

In this part of the article, we’ll delve into some of the present trends shaping the future of robotics.

- Collaborative Robotics (Cobots)

- AI and Machine Learning Integration

- Service Robotics Engineering

- Autonomous Vehicles and Drones

- Soft Robotics and Bioinspired Design

- Space Exploration and Planetary Robotics

Collaborative Robotics (Cobots)

Collaborative robot solutions, or cobots, are made to work alongside humans in a shared workspace.

These robots are rich with advanced sensors and safety features that help them safely interact with humans without traditional safety barriers.

Cobots are revolutionizing industries such as manufacturing, which enhance productivity by assisting human workers in tasks requiring precision, strength, or speed.

AI and Machine Learning Integration

AI (Artificial intelligence) and ML (Machine Learning) are impacting their significant role in enhancing the capabilities of robots.

Robots are more intelligent and adaptive, can learn from data, and can make informed decisions.

Machine learning algorithms enable robots to recognize patterns, improve their performance over time, and adapt to changing environments, making them more versatile and efficient in various applications.

Service Robotics Engineering

Service robot solutions are becoming increasingly prevalent in the healthcare, retail, hospitality, and logistics sectors.

These robotics engineering technologies can assist in patient care, customer service, inventory management, and food delivery.

The COVID-19 pandemic has fastened the adoption of service robots, particularly in healthcare settings, where robot solutions are used for disinfection and remote patient monitoring.

Autonomous Vehicles and Drones

The automotive and transportation industries are witnessing a surge in autonomous vehicles, including self-driving cars and trucks.

These vehicles utilize robotics and autonomous systems, AI, and advanced sensors to navigate and make decisions on the road.

Drones, another type of autonomous vehicle, are finding applications in industries like agriculture, surveillance, and delivery services, transforming how goods are transported and information is gathered.

Soft Robotics and Bioinspired Design

Soft robotics is a burgeoning field that takes inspiration from nature to create robots with soft, flexible, and deformable structures.

These robots are ideal for tasks that require delicate interactions, such as gripping fragile objects or navigating complex environments.

Bioinspired design principles are leading to robots that mimic the movement and behavior of animals, enabling new applications in areas like search and rescue.

Space Exploration and Planetary Robotics

Robotic exploration is extending our reach into space.

Robots like the Mars rovers conduct scientific experiments, analyze soil samples, and collect data on other planets.

As space missions become more ambitious, robots are vital in advancing our understanding of the cosmos.

Challenges of Robotics and Autonomous Systems

While robotics holds immense promise and potential in transforming industries and enhancing human capabilities, it’s essential to acknowledge that, like any technology, it comes with challenges and disadvantages.

As robotics and autonomous systems become more integrated into various aspects of society, it’s crucial to consider and address the potential drawbacks proactively.

In this section, we’ll explore some of the disadvantages of robotics-

- Job Displacement

- Initial Costs and Implementation Challenges

- Technical Complexity and Dependence

- Ethical and Social Concerns

- Human Interaction and Empathy

- Environmental Impact

- Loss of Craftsmanship and Artistry

Job Displacement

One of the robotics and autonomous systems most commonly discussed disadvantages is the potential for job displacement.

As automation and robots take over specific tasks, there is a concern that human workers may be replaced, particularly in industries where routine, repetitive tasks are prevalent.

This can lead to job losses, especially for workers in lower-skilled roles, and can contribute to economic and social disruptions.

Initial Costs and Implementation Challenges

Developing and implementing robotic systems can be expensive and complex.

The upfront costs of purchasing, programming, and maintaining robots can be significant, especially for small businesses and industries with limited resources.

Moreover, integrating robots into existing workflows may require substantial changes to processes and infrastructure, leading to disruptions and challenges during the transition phase.

Technical Complexity and Dependence

While robots can enhance efficiency, they also introduce technical complexity.

Operating, programming, and maintaining robots often require specialized knowledge and skills.

This dependence on specialized expertise can create a skills gap, making it difficult for businesses to find qualified personnel to effectively manage and troubleshoot robotic systems.

Ethical and Social Concerns

The increasing autonomy of robots raises ethical questions, particularly when it comes to decisions made by machines.

As robots take on more decision-making responsibilities, issues related to accountability, liability, and the potential for biased algorithms become pertinent.

Privacy and data security concerns arise when robots are rich with cameras and sensors that collect personal information.

Human Interaction and Empathy

While advancements in human-robot interaction are promising, robots still lack the emotional intelligence and empathy that come naturally to humans.

In sectors like healthcare, where human connection is vital, the absence of genuine human emotions and understanding can hinder the quality of care provided by robotic systems.

Environmental Impact

The manufacturing and disposal of robotic components can contribute to environmental concerns.

Robots’ production involves using raw materials and energy, potentially leading to resource depletion and carbon emissions.

Additionally, electronic waste disposal from obsolete robots can contribute to electronic waste pollution.

Loss of Craftsmanship and Artistry

In specific industries, introducing robotic automation can lead to declining craftsmanship and artistry.

For example, in traditional crafts and creative fields, the personal touch and uniqueness that human artisans bring to their work may be lost when automated processes take over.

Practical Applications of Robotics Technology

The widespread use of robots in business and other fields has unleashed previously unimaginable opportunities.

From industry and medicine to explorers and entertainers, robotics provides novel answers to complex problems.

Real-world experience and knowledge of implementation tactics are essential for successful robotics deployment.

This section will go into the many applications of robotics and autonomous systems.

- Industrial Manufacturing

- Medical and Health Care Systems

- Farming and Agricultural Practices

- Robotic Space Exploration

- Research and Academic Study

- Art and Amusement

Industrial Manufacturing

Robotics has found several important uses in manufacturing industries.

Increased output and product quality may result from robots automating mundane, time-consuming jobs. Automation and robots in production can-

- Recognize activities like assembly, welding, and material handling that might profit from automation.

- Determine which robot design (e.g., articulated arm, SCARA, delta) suits the job best.

- Incorporate sensing and imaging components to allow robots to understand their surrounding environment and respond accordingly.

- Write code for robots that lets you precisely control them and quickly change their setup.

Medical and Health Care Systems

Robotics and autonomous systems are revolutionizing the medical field by facilitating procedures, diagnoses, and patient care. Incorporating Robots into Medical Practices are following-

- Robotic-assisted surgery is best for delicate procedures.

- Create robots for use in telemedicine to facilitate remote doctor visits and patient monitoring.

- Create robots to aid in recovery from surgery or injury.

- Replace human pharmacists with robots to lessen the likelihood of pharmaceutical mistakes.

Farming and Agricultural Practices

Traditional farming methods are being disrupted by agricultural robots, which optimize resource use and boost crop yields. The use of robots in farming would entail-

- Utilize AVs to sow seeds, irrigate plants, and gather produce.

- Drones may monitor crops, look for pests, and accurately spray.

- Create automated devices to do weeding and fertilizing to reduce chemical consumption.

Robotic Space Exploration

When people cannot or should not enter an area, robots play a crucial role in discovering what lies there. Exploration in space and other environments may benefit from the use of robots in the following ways-

- Create robots capable of doing experiments, data analysis, and sample collection in hard-to-reach locations.

- Use a combination of sensors and cameras for orientation and data collection.

- Create a system that uses AI to make decisions on its own during missions.

Research and Academic Study

As it allows for theoretical and practical exploration, robotics has become an invaluable resource in the academy and the laboratory. These sector-based uses of robotics systems are-

- Putting Robots to Use in the Classroom and the Laboratory

- Introduce kids of all ages to the fundamentals of programming and engineering with the help of educational robotics kits.

- Create study designs investigating topics like AI, ML, and HRI. To further the subject of robotics, it is essential to collaborate with academic and research institutes.

Art and Amusement

Engaging and fun experiences may be manufactured with the help of robots. As a means of amusement, the use of robots-

- Make robots that people may engage with at fairs, museums, and other gatherings.

- Produce and perfect animatronics for film, television, and live theater use.

- Design machines that can create visual and aural works of art and music.

Robotics Technology: Practical Tips for Effective Usage

It takes a unique set of skills—including technical knowledge, imagination, and the ability to solve problems—to embrace robotics technology fully.

Knowing how to get the most out of robotics technology is crucial for every user, no matter how seasoned they may be.

Here, we will show you how to put robot technology to work for you in various situations with some straightforward advice.

- Know What You Want

- Picking the Appropriate Robot

- Study the Code Behind Robots

- Increase Sensing and Processing Capacity

- Be Safe Around Robots

- Rate Kinematics and Dynamics of Robots

- Make Use of Simulated Environments

- Keep up with the Latest Trends

- Network and Work Together

- Make Baby Steps and Improve

Know What You Want

Define your goals before beginning to work with robot technology.

With a clear objective in mind, you can better determine which technology and resources will help you achieve your automation, efficiency, or creativity goals.

Picking the Appropriate Robot

Choosing a robot that is well-suited to the task at hand is essential.

Think about things like the difficulty of the job, the available area, the amount of weight, and the need for mobility.

Based on your requirements, choose from various robot types, including industrial, collaborative (cobot), mobile, and more.

Study the Code Behind Robots

Learning to code is a must if you want to work with robots.

Study Python, C++, and ROS (Robot Operating System), three of the most popular programming languages used in robotics.

To successfully program and operate the robot, you must get familiar with its control software, interface, and APIs.

Increase Sensing and Processing Capacity

Robots are depended on their sensors to gather information about their surroundings.

Learn about the many kinds of sensors available, such as visual sensors (cameras, lidar, ultrasonic, etc.) and mechanical ones (force, torque, etc.).

Develop an understanding of perception algorithms, sensor calibration, and data processing to give intelligent robots a leg up when making judgments.

Be Safe Around Robots

Safety must always come first when using robot technology, particularly in team settings.

Protect robots by installing sensors that detect human presence, safety barriers, and emergency stop buttons.

Avoid mishaps by adhering to safety procedures and instructing users to operate the equipment correctly.

Rate Kinematics and Dynamics of Robots

To successfully program the motion and interaction of robots, it is necessary to have a firm grasp of their kinematics (movement) and dynamics (forces).

Dynamic control requires knowledge of forward and inverse kinematics and the effects of inertia and friction.

Make Use of Simulated Environments

It is recommended to use simulation software to evaluate and improve algorithms and tactics before deploying robots in real-world circumstances.

Using a simulation environment, you can test various scenarios, tweak settings, and identify problems before committing to a real-world rollout.

Keep up with the Latest Trends

The area of robotics changes quickly, with new developments in technology and methodology occurring often.

Attending robotics-related events like conferences, seminars, and online courses is a great way to stay abreast of the field’s most recent developments, research papers, and inventions.

The only way to become an expert in robotics is to keep learning about it.

Network and Work Together

Participate in forums, communities, and social media sites dedicated to robotics projects.

Sharing your robotics projects with other enthusiasts, experts, and academics may help you learn from one another and advance your work.

Make Baby Steps and Improve

Let’s start with smaller tasks using robot technology.

You may pinpoint problems, gain insight from your experiences, and hone your abilities in this iterative manner.

Gaining practical experience is critical to laying the groundwork for success when taking on more challenging endeavors.

Cost Factors of Robotics Technology

Robotics prices vary greatly depending on the robot type, talents, complexity, and market or application. Costs associated with robots include the following-

- Type of Robot

- Functions, Abilities, and Options

- Customization

- Combining and Programming

- Repairs and Upkeep

- Business Sector and Use

- Gains from Scale

- Robots, Used and Refurbished

Type of Robot

The price tag of various robots varies widely.

Industrial robots are often more costly since they are built for particular jobs and require high accuracy.

Due to their reduced complexity and increased emphasis on human safety, collaborative robots (cobots) are typically less expensive.

Functions, Abilities, and Options

A robot’s price depends on its capabilities and characteristics.

Robots with more complex sensors, AI skills, and programming are often more costly.

Precision, complexity, and autonomy all increase the price of robots built for specific purposes.

Customization

Application-specific robotics systems might be more costly than general-purpose ones.

Creating robots to fit specific needs might add to the expense of engineering and development.

Combining and Programming

The whole price of robotics projects includes the hardware, programming, and setup.

Integrating the robot into preexisting processes and infrastructure may also require extra programming, simulation, and control software investments.

Repairs and Upkeep

The price of ongoing maintenance and support must be factored in.

The total cost of ownership may increase due to the need for routine servicing, software upgrades, and technical support to keep the robot running at peak efficiency and for as long as possible.

Business Sector and Use

Robotics engineering expenditures range in price from industry to industry due to varying needs.

For instance, manufacturing, healthcare, and aerospace robots may have distinct pricing structures owing to the varying needs and requirements of these industries.

Gains from Scale

Discounts are available from manufacturers when buying a large number of robots.

Robotics engineering per-unit costs may be decreased through extensive adoption within a company or across many facilities.

Moreover, robot costs may change depending on market conditions and consumer demand. Prices may drop as more companies join the market and the robots sector develops.

Robots, Used and Refurbished

You may save a lot of money by purchasing a used or refurbished robot instead of a brand-new one.

Used robots like this may have been reconditioned and tested to ensure they still function well. For specific uses, this may be the most economical choice.

New and advanced robotics projects may be more expensive than older ones because of the time and money needed to create them.

Future of Robotics Projects

An era of unprecedented innovation and revolution is ahead for robotics technology.

Future robots will be more innovative, flexible, and interwoven into our everyday lives as we continue to see AI, machine learning, and sensor technology developments. Autonomous automobiles will revolutionize urban travel and logistics.

Robotics engineering in the industry will usher in a new age of tailored, efficient production. In contrast, medical robots will improve surgical accuracy and individualized patient care.

In the future, humans and robots will work together even more seamlessly, with robots aiding us in jobs that call for accuracy, strength, and automation.

Developing soft robotics projects and bioinspired designs will allow robots to closely resemble organic beings, traverse complicated situations, and interact with people.

The future of robotics engineering promises innovation, efficiency, and endless human-robot cooperation as robots move farther into space, explore the oceans, and transform education and entertainment.

Final Thoughts

The fascinating history of human creativity and technical progress is encapsulated in robotics systems.

The development of robotics projects exemplifies humanity’s never-ending quest to break new ground and mold the future, from the simple mechanical wonders of the past to the complex robots of the present.

It is essential to remember, among all the talk about automation and AI, that robots’ real power rests in cooperation, not rivalry.

Robotics engineering may supplement human talents by carrying out menial jobs so that people can devote their time and energy to more complex endeavors that need imagination, analysis, and compassion.

However, as robotics and automation technology gain greater independence, issues of ethics and accountability become increasingly pressing.

The versatility of robotics and automation systems is shown by their widespread use in a wide range of sectors for solving a wide variety of problems.

We must encourage cross-disciplinary cooperation and balance technological advancement and ethical concerns to realize robots’ full potential.

Let us go ahead in excitement over robotics projects limitless potential while considering the more significant social effects and ethical concerns that will shape the future we create.

Robotics—a computer science and engineering discipline—covers robot design, building, and operation. The goal of robotics and automation is to build intelligent robots that help humans work. Robotics projects are varied.

American inventor George Devol founded Unimation and invented industrial robots. GM bought Unimate, a hydraulic arm that lifted heavy things, in 1954, making it the first industrial robot.

A robot is any machine with an automated control system that can execute tasks humans usually do by themselves. Therefore, robotics projects refer to the branch of engineering concerned with studying robots and their use.